|

|

Liquid Level Control Switch |

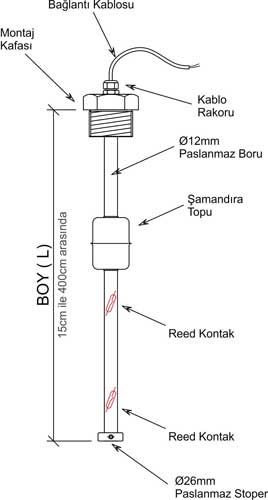

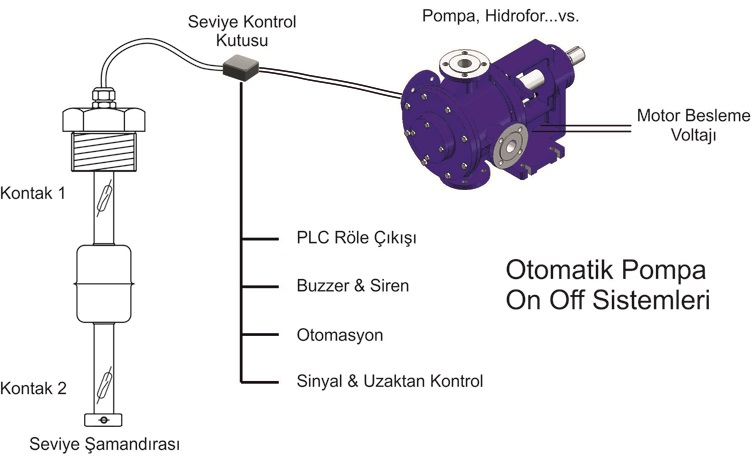

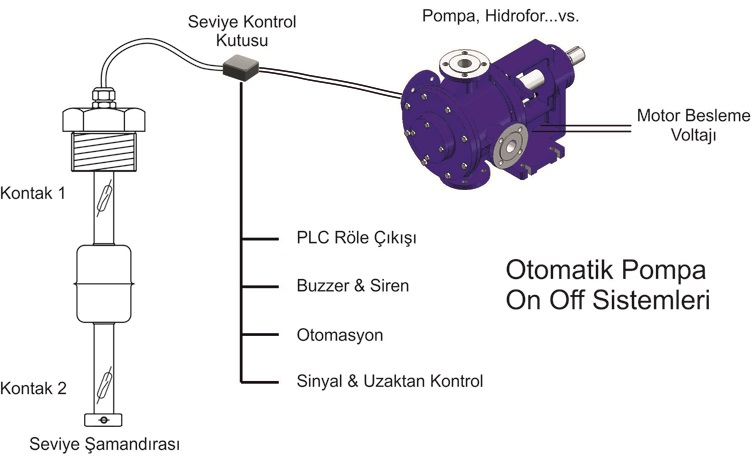

All kinds of liquids are used in the boiler and in the tanks to get a warning when the liquid falls or rises to a certain level. In order to keep the level in the tank automatically at a certain level, the liquid can be held between the lower and upper level by putting in two points. Depending on the system you need, we can also measure the values at different distances or get warnings by putting dry contacts on 3, 4, 5 or 6 different points. Different system combinations can be established by connecting these levels to the panel, panel, PLC or automation system. You can contact for technical details and suitable model options by telephone.

|

Prices |

: Please contact us for custom manufacturing. |

| Features |

|

Usage areas |

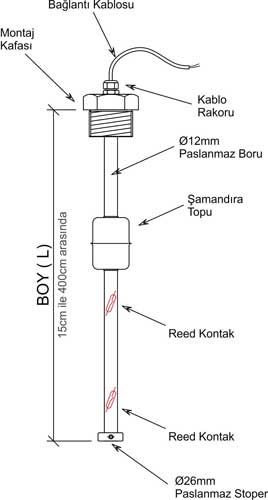

Body Structure

|

: Stainless Steel |

Generator fuel tanks |

| Float |

: Polyurethane & Chrome

|

Drinking water in the store |

| Leght |

: 15cm - 400cm |

In cooling water tanks |

Working Value

|

: Contact |

in liquid soap boilers |

Operating temperature

|

: 0 - 80ºC |

Sebil deposits |

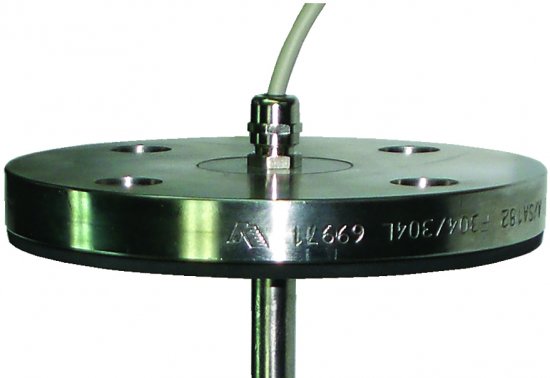

Tank Connection

|

: 1¼ ", Flange, Custom Size

|

Tekne Su tanklarında |

Electrical connection

|

: 6x0,50mm² Cable (50cm) |

Ship in Tanker Boilers |

Operating Voltage

|

: 12 V & 24V |

In liquid oil boilers |

| Max. Contact Quantity |

: 5 Quantity / Max. |

Bilge waters in tanks |

| |

|

|

| |

|

|

| |

|

|

|

|

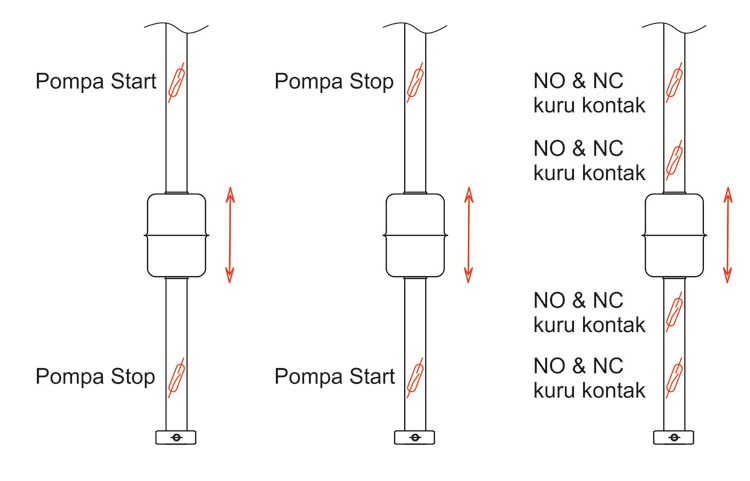

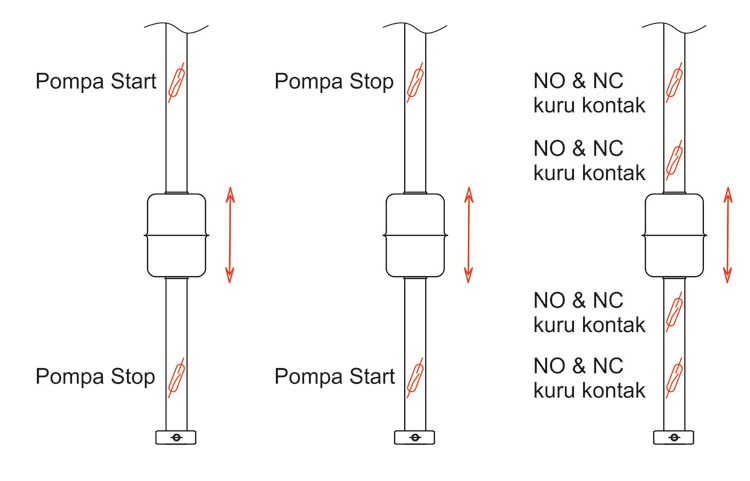

| Normale Open Contact |

|

| Normale Closed Contact |

|

This model can be used to start and stop the pump when the liquid level rises and falls.

Up to 5 contacts on a float can be connected at the same time and can be calibrated for lower alarm, upper alarm or different combinations.

|

Double Contact

Normally open and closed contact same reed

|

Cantilever Side Mounting Cantilever Side Mounting

|

Connection Scheme example

|

A sample connection diagram above is shared. You can easily mount your system as mentioned above. Please contact our company for different models and operating systems.

|

|