|

|

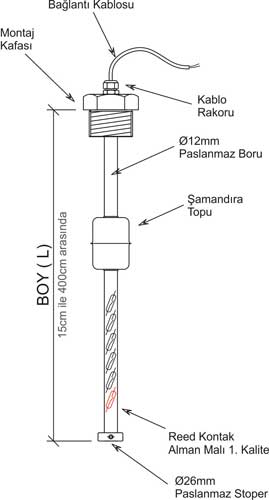

Liquid Level Sensor |

Such liquid level sensors used to determine the level of liquids in tanks and reservoirs can be found in the industrial field, shipbuilding, automobiles and caravans, aircraft and unmanned aerial vehicles, thanks to the stainless steel body construction preferably made of polyurethane or stainless float ball, in air vehicles, fuel tanks or water tanks. You can use it in tanks and tanks of all sizes and sizes with standard tiller and special manufacturing options.

|

Prices |

: Please contact us for custom manufacturing. |

Features

|

|

Usage areas |

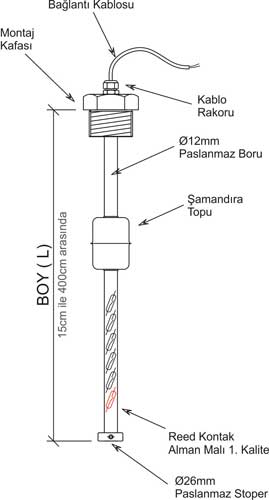

Body Structure

|

: Stainless Body

|

In fuel tanks |

| Float |

: Polyurethane & Stainless

|

Fresh water in the store |

| Length |

: 15cm - 400cm |

Machine in lubrication boilers |

Working Value

|

: 4-20mA, Ohm, 0-5V |

In chemical liquid tanks |

max. temperature

|

: 0 - 90ºC |

Cars, caravan storage |

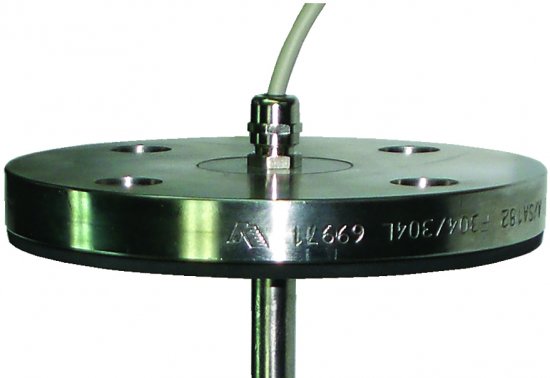

Tank Connection

|

: 1¼ ", Flange, Custom Size

|

In boats, yachts, ship tanks |

Electrical connection

|

: 2x0,50mm² Cable (50cm)

|

In cooling water systems |

| Voltage |

: 12 V & 24V

|

Well, Pool water measurements |

| Gauge |

: Digital & Analog Compliant

|

In fire-fighting vehicles |

| Extra Contact |

: Plain

|

Milk, fruit juice boilers |

| |

|

In acid tanks |

| |

|

|

|

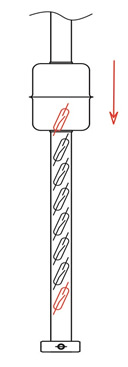

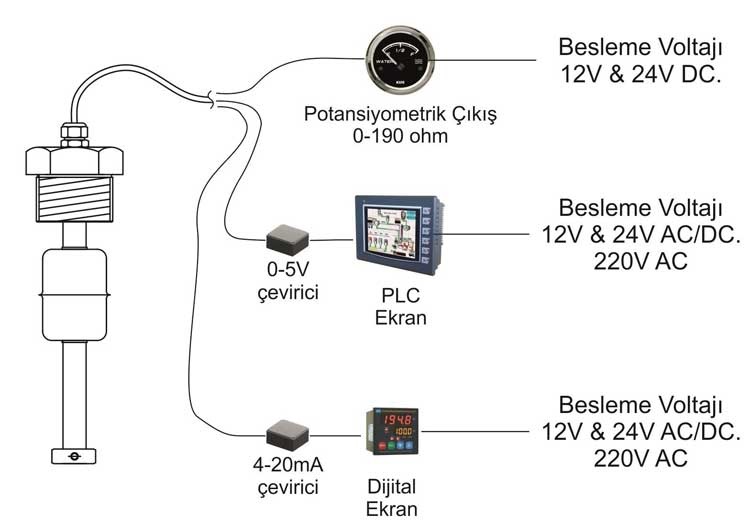

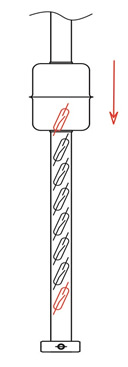

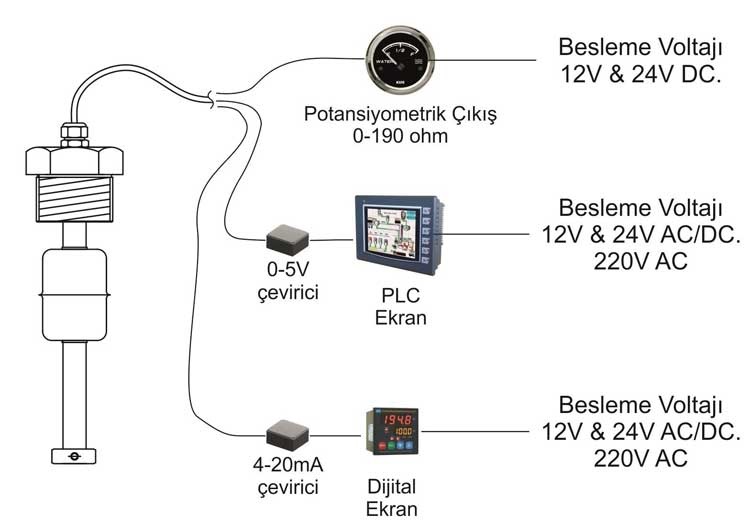

Sensor Working Principle |

The liquid level sensors, electricity system and circulation which we manufactured by using the magnetic field effect in the level measurement systems are completely isolated from the liquid and a healthy and long lasting level measurement system is established. A magnetic field is created on the pipe where the float ball moves up and down with the liquid. Reed contacts placed inside the pipe during manufacturing are affected by this magnetic field and change to electrical value. In accordance with the needs and the system of this electrical value change obtained,

- 4-20mA output value,

- 0-5V output rating

- The potentiometric value is obtained as the output (adjustable) value.

In addition, all of the level measurement sensors we manufacture have been kept at the highest quality level using European origin or domestic raw materials and it has been possible to use for a long time without problems.

|

|

Connection Schemes |

The electrical connections of the level sensors are very easy. The device, which is manufactured in accordance with the display or indicator that you will follow the level, is included as 2 wired or 3 wired. Test and calibration are done in the workshop environment for 2 years with the manufacturer's guarantee by means of plug-and-play operation.

|

|